Sorting herring co-products and monitoring lipid oxidation of the different fractions

When fish is processed into fillets, all co-products (head, backbone, caudal fin, skin, and intestines) typically end up in one bin and are subsequently sold for fish meal/fish oil production. The fact that the co-products are mixed allow blood, enzymes and lipids from e.g., the viscera and head parts to contaminate the cleaner parts like the backbones and tails, accelerating e.g., lipid oxidation, hydrolysis and bacterial growth which quickly reduces the quality. This prevents further upgrading of the co-products to high-quality food ingredients, calling for changes in the existing logistics.

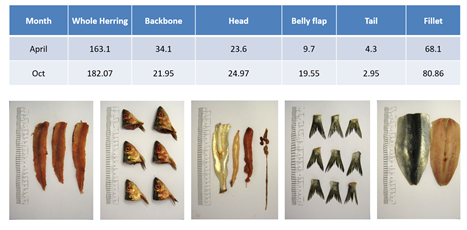

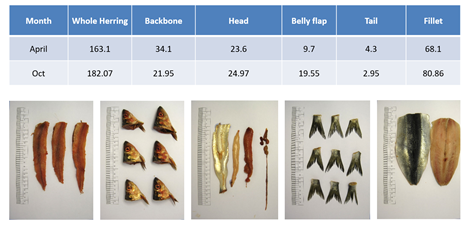

To facilitate for food production, the herring processing company Sweden Pelagic (Martin Kuhlin and Jörgen Nyberg) has together with Chalmers University of technology (Haizhou Wu, Bita Forghani, Mehdi Abdollahi and Ingrid Undeland) developed a new sorting technology for herring filleting co-products, which allow successful separation of four clean fractions: backbones, heads, tails and intestines + belly flaps. The new technology is developed based on re-building of a filleting line for pelagic fish and largely improves the chances to optimize the use of the different fractions for subsequent production of food raw materials and ingredients such as minces, protein isolates, hydrolysates and oils.

In a recently published paper, it was confirmed that sorting of herring co-products prior to subsequent ice storage in minced form reduced the intensity of rancidity development in more stable parts of the co-products, such as the backbones as they are no longer mixed with more sensitive parts like the heads. The head fraction was in fact revealed to be by far the least stable part, something which correlated to its high content of hemoglobin, its high activity of the enzyme lipoxygenase, and its low level of the antioxidant tocopherol.

Surprisingly, the fat content or level of polyunsaturated fatty acids in the different co-product fractions did not at all control their susceptibility to rancidity development. This knowledge is of high importance to predict the oxidative stability of different fish raw materials based on their composition.

The paper, “Lipid oxidation in sorted herring (Clupea harengus) filleting co-products from two seasons and its relationship to composition” is published with open access in the journal Food Chemistry. It was based on herring co-products from Sweden Pelagic, however, the sorting technology can be transferred also to other fish species.

Figure 1. The weight (grams) distribution of the sorted fractions and photo documentation

Read the publication here:

Read the publication here:

“Lipid oxidation in sorted herring (Clupea harengus) filleting co-products from two seasons and its relationship to composition” by Haizhou Wu, Bita Forghani, Mehdi Abdollahi, Ingrid Undeland, 2 November 2021, Food Chemistry

https://doi.org/10.1016/j.foodchem.2021.131523