Nutritional composition of herring co-products from innovative sorting technology

In the fishing industry, about 70 % of the total landings of fish are processed into fillets, an operation which results in 20–80 % (w/w) of fish co-products (head, backbone, caudal fin, skin, and intestines). Utilizing these co-products for food rather than feed or other lower-value applications would be a promising way to meet the increasing demand for seafood or fish-derived ingredients.

Today co-products from the pelagic fish industry are commonly mixed together in one container after the filleting operation, allowing blood, enzymes and lipids from e.g., the viscera and head parts to contaminate the cleaner parts like the backbones and tails, accelerating e.g., lipid oxidation, hydrolysis and bacterial growth which quickly reduces the quality. This prevents further upgrading of the co-products to high-quality food ingredients, calling for changes in the existing logistics.

To facilitate for food production, the herring processing company Sweden Pelagic (Martin Kuhlin and Jörgen Nyberg) has together with Chalmers University of technology (Haizhou Wu, Bita Forghani, Mehdi Abdollahi and Ingrid Undeland) now developed a new sorting technology for herring filleting co-products, which allow successful separation of four clean fractions: backbones, heads, tails and intestines + belly flaps. The new technology is developed based on re-building of a filleting line for pelagic fish and largely improves the chances to optimize the use of the different fractions for subsequent production of food raw materials and ingredients such as minces, protein isolates, hydrolysates and oils.

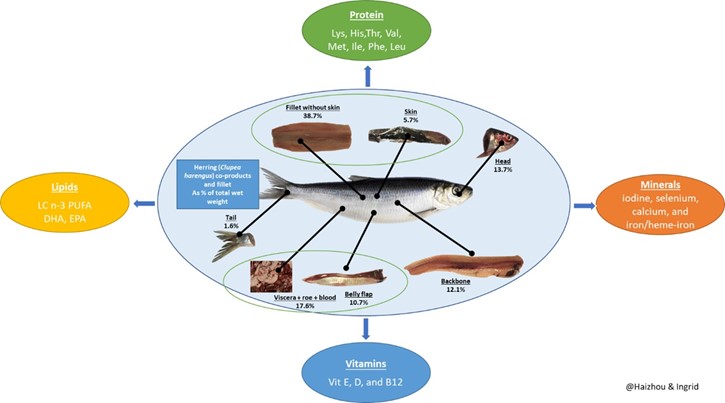

In a recently published paper, weight distribution, proximate composition, fatty acids, amino acids, minerals and vitamins were investigated both in the fillet and in the four sorted co-product cuts derived from spring and fall herring (Clupea harengus). The herring co-product cuts constituted ∼ 60 % of the whole herring weight, with backbone and head dominating. Substantial amounts of lipids (5.8–17.6 % wet weight, ww) and proteins (12.8–19.2 % ww) were identified in the co-products, the former being higher in fall than in spring samples. Co-product cuts contained up to 43.1 % long-chain n-3 polyunsaturated fatty acids (LC n-3 PUFA) of the total FA, absolute levels peaking in viscera + belly flap. All cuts contained high levels of essential amino acids (up to 43.3 %), nutritional minerals (e.g., iodine, selenium, calcium, and iron/heme–iron), and vitamins E, D, and B12. Co-products were, in many cases, more nutrient-rich than the fillet and could be excellent sources for both (functional) food and nutraceuticals. The knowledge about the distribution of macro- and micronutrients among the different co-product cuts could contribute to a changed utilization pattern of herring, with more going to food and less to feed.

The paper, “Five cuts from herring (Clupea harengus): comparison of nutritional and chemical composition between co-product fractions and fillets” is published with open access in the journal Food Chemistry X. It was based on herring co-products from Sweden Pelagic, however, the sorting technology can be transferred also to other fish species.