Flocculation with Centrifugation Technology: Herring Liquid Side-Streams

Overview of the Environmental and Economic Sustainability Assessment

The growing demand for convenience seafood products has caused significant rise in the volume of side streams. These side streams primarily go to feed production, but are sometimes also treated as waste, leading to both environmental consequences and economic losses. Disposal of solid waste presents a major environmental problem, as it can lead to pollution and other negative effects on ecosystems. Nevertheless, there is a promising alternative: valorising side streams. This valorisation can not only reduce environmental impacts but also lead to economically valuable products.

The WaSeaBi project, an EU-funded Horizon 2020 initiative (grant agreement no. 837726), plays a significant role in advancing novel technologies in this regard. One of the value chains analysed within the project's scope is based on herring liquid side-steams. Extensive research has been conducted on the processing of herring liquid side-steam using flocculation followed by centrifugation technology to obtain valuable protein biomass. This novel process has been tested and implemented by Chalmers University of Technology at a pilot plant in Sweden using test equipment supplied by Alfa Laval. To ensure that the implementation of this technology does not result in adverse environmental or economic consequences, a comprehensive sustainability analysis was conducted throughout the project's development and operational phases, using Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) methodologies.

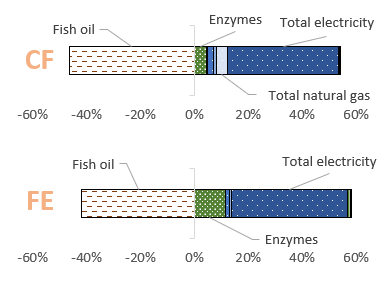

Environmental Sustainability Assessment

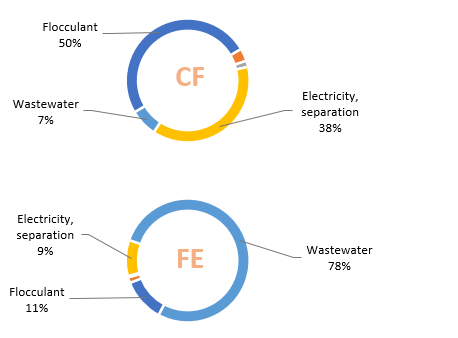

The carbon footprint (CF) impact category highlighted that the flocculant has the most significant environmental impact. Additionally, the electricity consumed in the separation phase also makes a substantial contribution. In the freshwater eutrophication (FE) impact category, the wastewater generated after centrifugation has a substantial impact.

Overall, these findings highlight the importance of carefully considering the choice of flocculant and its potential environmental implications in this value chain. Also, efforts to optimize electricity consumption during separation could lead to more environmentally sustainable outcomes for the assessed system.

Economic Sustainability Assessment

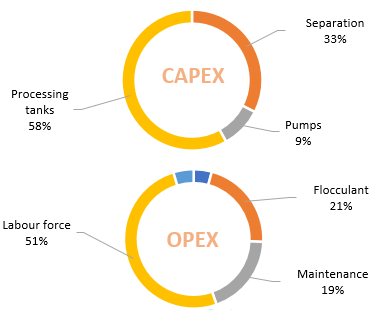

The implementation of this technology could potentially lead to the recovery of significant amounts of phosphorus further to the proteins. This is expected to improve wastewater composition compared to the business-as-usual case. As a result, operational costs associated with wastewater treatment would be reduced. The analysis also shows that the most substantial capital expense (CAPEX) is associated with processing tanks. Additionally, labour force, flocculant, and maintenance constitute a noteworthy portion of the operational expenses (OPEX).

- Functional Unit: 1 kg of protein biomass.

- System Boundaries: Cradle-to-Gate.

- Method: Environmental Footprint (EF) 3.1.